GCG was engaged to provide specialist technical support to the Asset Owner and Designer. GCG’s remit included the design of compensation grouting works during the preliminary, detailed and construction stages, site support during construction and close-out reporting. For the compensation grouting, curved tube à manchettes (TAMs), installed by directional drilling, were used to provide access for controlled grout injection at a level between the tunnel and the viaduct foundations. The grouting induced heave, which reversed the tunnelling generated settlements. The net result was that the viaduct only experienced small and acceptable settlements and distortions. Real time monitoring was a key aspect of the technique, which allowed proper management of the grouting and tunnelling activities.

References

Iannotta, F., Pigorini, A., Mair, R. J., Facibeni, L., Harris, D. I., Menkiti, C. O., Leoni, F. (2007). Applicazione della tecnica del compensation grouting per il controllo dei cedimenti indotti dallo scavo di gallerie al di sotto di un viadotto ferroviario. Proc. XXIII CNG – Padova, Abano Terme

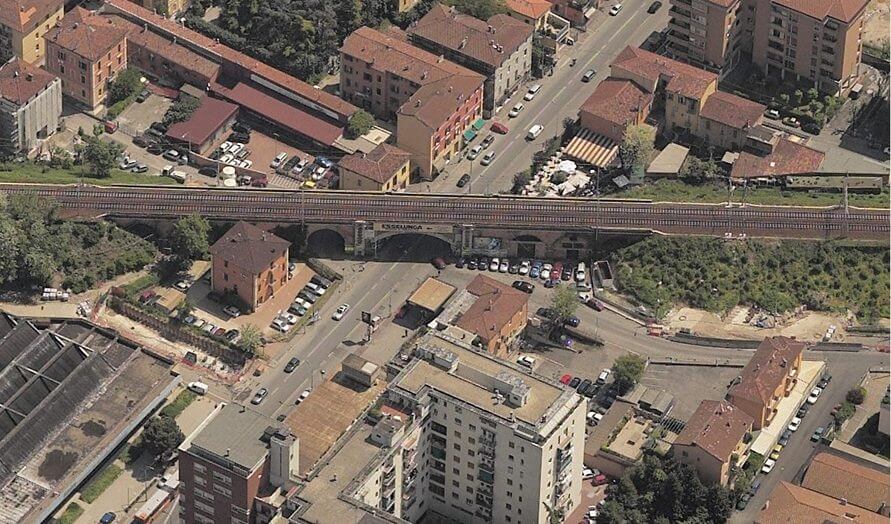

Location